by

Warehouses are essential for millions of businesses that rely on ready-made inventory to propel their operations. Once a business reaches capacity in its first location, it will inevitably need to expand into another, or multiple, if necessary.

In a world of constant expansion, how will businesses be able to juggle the inventory, logistics and operation of multiple locations?

The most comprehensive solution is multi-location management software systems, which involve the technical management of operations in multiple warehouses across different locations. The term covers all operations, including inventory, staff, shipping, storage and movement of goods.

For ecommerce organizations, multi-location management software has a more specific meaning, centered around the shipping and fulfillment of products from multiple warehouses, along with any related logistics.

Does Your Business Need Multi-Location Inventory Management?

If your business is planning on expanding beyond a single warehouse or location, the answer to this question is a resounding yes.

Managing locations at scale is a challenging task, even for experienced professional organizations. From cross-warehouse communication gaps to stock transfer and a lack of general oversight, having multiple locations can quickly spiral into a disaster if you're not careful.

As with many ventures, as you scale eventually spreadsheets won't be able to cut it. By having a dedicated multi-location inventory management system, you can consolidate all of your information into a single, streamlined solution based around automation — making your life easier and ultimately more profitable.

Inventory Management Challenges

Managing your inventory for growing businesses can be difficult, especially as you expand into multiple locations and warehouses. Some of the potential challenges you may face include:

Communication.

Communication and collaboration are critical aspects of any business, especially those with a wide net of customers and locations.

With multiple disparate warehouses — each with its own set of equipment, processes and best practices — communication can quickly break down, leading to errors and preventable mishaps.

When establishing multiple locations, a multi-location inventory management solution can ensure a consistent, arching communication plan is in place all the way to point of sale (POS) and checkout.

Inventory control.

The more locations and warehouses you employ, the more difficulty you will have with inventory issues, whether it's overstocking or broader inventory loss.

This is a natural result of an extended supply chain and can affect any large or growing organization. By implementing a multi-location inventory solution, you can ensure that there are plans in place to manage and track inventory levels.

Order bottlenecks.

Poor inventory management over multiple locations and warehouses can lead to bottlenecks, slowing warehouse operations and production, and inducing irate customers. This is especially prevalent if each warehouse has its own set of operational guidelines in place.

With an effective order management solution, you can consolidate warehouse operations and guidelines into a simple, streamlined affair.

Advantages of Multi-Location Inventory Management

As the need for more warehouses increases as a company grows, many find that spreadsheets or small-scale software solutions aren’t up for the task. With the help of multi-location inventory management software, you can make use of several advantages, including:

Faster deliveries.

By having multiple warehouses, you can help to expedite the flow of goods in and out. Additionally, the more warehouses you can maintain, the closer the products will ultimately be to the customers.

With ecommerce, this also extends to concepts such as micro-fulfillment centers. These smaller warehouses have been introduced by companies such as Amazon and Walmart to ensure that deliveries can be delivered in hours instead of days or weeks.

Lower costs.

Being able to manage goods in facilities spread out geographically can help streamline distribution while cutting down on costs, from logistics to fulfillment.

For example, if you have a single warehouse in Chicago but a significant customer base in New York, the shipping costs can add up quickly. By adding an additional warehouse in New York, the decrease in shipping and delivery costs can offset the price of a second location.

Increased customer satisfaction.

With multiple warehouses — and a software system to match — organizations will be better equipped for quicker deliveries at decreased costs.

How vital is faster delivery to customers? According to one study by eFulfillment Service, more than 75% of customers desire same-day or express shipping — something only offered by around half of retailers.

If you’re able to deliver on their expectations, you can quickly garner a dedicated customer base.

Flexible inventory organization.

The use of multiple warehouses can be highly beneficial for businesses with a diverse set of products to match their diverse customer base.

If a company has two products that sell well but in different areas, by positioning separate warehouses in the regions, they are able to assist their customers more efficiently while ensuring consistent profits.

Reduced carbon footprint.

Housing and managing inventory in different warehouses can significantly reduce carbon emissions by minimizing the distance traveled to deliver orders. With multiple warehouses operating closer to a broader base of customers, the amount of fuel emissions by vehicles or air travel can be reduced.

Additionally, studies have indicated that dedicated inventory management systems, through their advanced understanding of travel constraints and costs, can work to greatly decrease your carbon footprint and lead to more sustainable business practices.

Lowers risk.

The COVID-19 pandemic has shifted how many businesses approach warehouses, as the outbreak highlighted how vital the use of multiple warehouses could be.

Consider the pandemic restrictions and how different they were depending on which state, city or country you were located. If your business had a single warehouse in a location that was locked down, you would have had a more difficult time returning to the status quo than if you had multiple warehouses in multiple locations.

This extends to other unforeseen events, such as natural disasters. By using multiple warehouses and through the use of a multi-location inventory management system, you can work to reduce the potential of any catastrophic events.

How to Successfully Manage Multi-Location Inventory

Managing multiple locations and warehouses can be challenging, even for experienced companies and teams. When starting, consider the following recommendations:

Implement multi-location inventory management software.

This is the first step for any multi-location project, as the right solution can transform your business.

Implementing a system that effectively manages warehouse distribution provides a bevy of other benefits, which can make order fulfillment more accurate, efficient and transparent.

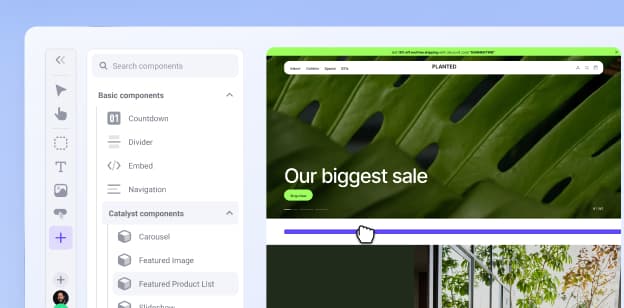

BigCommerce accomplishes this through the integration of apps into their store. Instead of having to use or purchase an entirely new software suite, you can enable multi-location inventory with a one-click add-on.

Strategically locate warehouses.

As discussed above, where your warehouses are located is critical to your business's growth and your multi-location project's success.

You will want to position your warehouses close to each other while ensuring they're near their targeted customer base. It can be a tricky process, but it can provide savings on logistical and transportation costs.

Additionally, you'll want to map out whether your warehouses are located in urban, rural or suburban areas, as this can affect the costs of rent, taxes and labor.

Plan for demand.

When crafting your multi-location plan, make sure to understand where your demand is. It helps no one to place a warehouse in a location with a minimal customer base, as the costs of maintaining a warehouse may not end up worthwhile in the long run.

By understanding customer demand, you can strategically set up a multi-location project that takes advantage of what customers want, leading to greater consumer satisfaction and overall profitability.

Optimize your warehouse layout.

Take time to optimize each of your multiple locations in order to ensure that inventory is as close as possible to the correct customer base and that they are grouped with similar product types.

From detailed maps to itemized workstations, proper optimization of your warehouse can determine the success of your entire multi-location project.

Set safety stock.

To successfully manage inventory across multiple, often disparate warehouse locations, you need to fully understand when to purchase more materials — a process that can be hampered if your products are spread out across a large area.

By having a set amount of safety stock for each of your products, you can track reorder points and prevent stockouts to ensure unnecessary delays or missed deliveries never occur.

How to Increase Ecommerce Sales

Explore our collection of free resources designed to help you scale smarter and accelerate your online growth from $1 million to $100 million.

The Final Word

When the time comes to expand to multiple warehouses, ecommerce merchants have a lot to consider. It is a potentially valuable exercise that comes with its unique set of challenges, from onset logistic issues to maintaining proper inventory levels.

Ultimately, any merchant would be wise to implement a powerful multi-location ecommerce platform that turns every order into a piece of actionable and meaningful data — without unneeded costs, time and effort.